Views: 0 Author: Site Editor Publish Time: 2013-03-08 Origin: Site

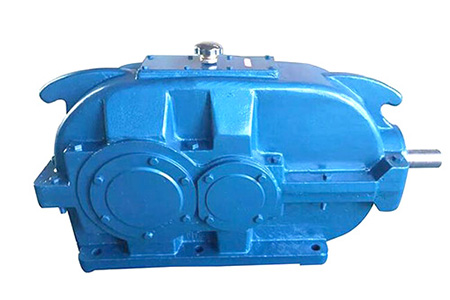

1. The gear is carburized and quenched with high-quality alloy steel, the tooth surface hardness is as high as 60±2hrc, and the tooth surface grinding accuracy is as high as 5-6.

2. Using computer shaping technology to pre-shape the gears, which greatly improves the carrying capacity of the reducer.

3. From the box body to the internal gear, it adopts a completely modular structure design, which is suitable for large-scale production and flexible selection.

4. Standard reducer models are divided according to the form of decreasing torque. Compared with the traditional equal ratio division, the power waste is avoided.

5. Design and manufacture with cad/cam to ensure the stability of quality.

6. Various sealing structures are adopted to prevent oil leakage.

7. Multi-directional noise reduction measures ensure the excellent low noise performance of the reducer.