Views: 0 Author: Site Editor Publish Time: 2016-10-12 Origin: Site

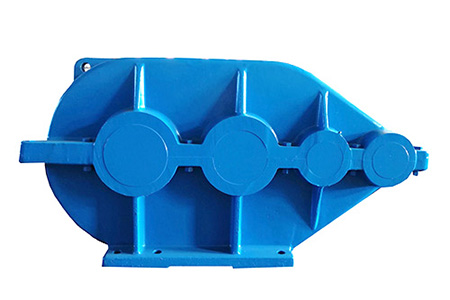

Cranes are widely used in docks, construction industry, steel plants, and other construction industries that need to lift heavy objects. The crane reducer is mainly used in the four major mechanisms of crane lifting, running, slewing and luffing. According to the hardness of the tooth surface, the commonly used crane reducers in my country are divided into soft tooth surface, medium hard tooth surface and hard tooth surface gear reducers. According to the installation method, they are divided into horizontal, vertical, packaged, and suspended packaged types.

How to better maintain the crane reducer in normal use is very important. Today, Jiangsu Taixinglong Reducer Co., Ltd. tells everyone how to do better maintenance to extend its service life and work efficiency.

1. Check the anchor bolts frequently to ensure that they are not loose, fall off or break.

2. Check the reducer case every day, and the temperature at the bearing should not exceed the allowable temperature. When the temperature exceeds 40°C at room temperature, check whether the bearing is damaged, whether it is installed improperly or lacks lubricating grease, whether the load time is too long, and whether the operation is stuck.

3. Check the lubrication parts. During the initial use of the wire rope electric hoist, change the lubricating oil every three months and clean the cabinet to remove metal chips. Change it once a half year to a year later. The lubricating oil must not leak. According to the cleanliness of the lubricating oil, the amount of oil should be moderate .

4. Pay attention to the sound of gear meshing. When the noise is too high or there is abnormal impact sound, open the box to check whether the shaft and gear are damaged. Under normal conditions, the sound is even and brisk, and the noise does not exceed 85dB.

5. Check the gearbox shaft with a magnetic or ultrasonic flaw detector. If cracks are found, replace it in time.

6. The shell of gantry crane electric hoist shall not be deformed or cracked.

7. When one of the following conditions occurs in the reducer parts, they should be scrapped.

① The gear has cracks and broken teeth.

②When the tooth surface pitting damage reaches 30% of the meshing surface or the depth reaches 10% of the original tooth thickness,

③The first-stage meshing gear of the lifting mechanism wears up to 10% of the original tooth thickness, and other meshing gears should be scrapped when the wear reaches 20% of the original tooth thickness; the first-stage meshing gear of other mechanisms wears up to 15% of the original tooth thickness. Other meshing gears should be scrapped when the wear reaches 25% of the original tooth thickness; when the gears in the open gear transmission reach 30% of the original tooth thickness, the gear should be scrapped.

④ When the gantry crane reducer shell is seriously deformed, cracked and has no repair value, the part shall be scrapped.